Led strips are strips, usually sold in 5 meter spools, made up of different numbers of led chips. The led strips used and installed in the correct way can have a duration of up to 50 thousand hours.

There are some common mistakes that are made in the installation of LED strips that compromise their operation.

Let’s see 8 tips to safeguard the life span of the strip and avoid unpleasant surprises after installation:

- Do not dirty the led strip with paint

- Use suitable profiles for heat dissipation

- Correctly remove the led strip

- Observe the maximum lengths per feed point

- Follow the cut lines to make changes on the strip

- Fold the strip in the correct direction

- Pay attention to the voltage indicated on the strip for its use

- Use led strips with correct IP degree

1) Do not dirty the led strip with paint

Often the LED strips are installed when the work is not yet completed, it may happen that during the finishing of the walls or the renovation works the LED strips might get dirty with paint. This worsens the color of the light emitted by the led chip, so we may see sections of light of the correct color where the led strip has remained intact and sections of light with a false color where the paint has covered the chip.

In case of color painting, for example red color, we may see a pink light emanating from the led strip, this error is caused by the led chip cover.

So it is good to always be careful not to dirty the LED strip with paint of any color or with other materials that could ruin it.

In the event that there are traces of paint on the strip it will be possible to clean it gently with a damp cloth and then wipe it with a dry cloth, before turning it on make sure that the strip has dried completely.

2) Use profiles suitable for heat dissipation

Most of the led strips need aluminum profiles for heat dissipation.

Installing a strip without a suitable profile can compromise the life span of the strip as well as overheating and damaging the surface on which it has been applied.

3) Remove the led strip correctly

It may happen that you want to remove the LED strip to install it on a different profile or to move it after an incorrect application. This action can be done safely, without damaging the LED chips and without having “holes” in the lighting.

It is important to gently remove the LED strip, accompanying it with the other hand throughout the removal phase. In this article a video where you can see the correct way to remove a led strip.

Do not pull the strip with force and snap, do not press hard on the LED chips, this will make them break highlighting the “holes” along the light line of the strip.

4) Respect the maximum lengths per feed point

This is important to avoid voltage drops and not see differences in brightness between the part closest to the power point (where the light will be more intense) and the most distant part (where the light will be dimmer).

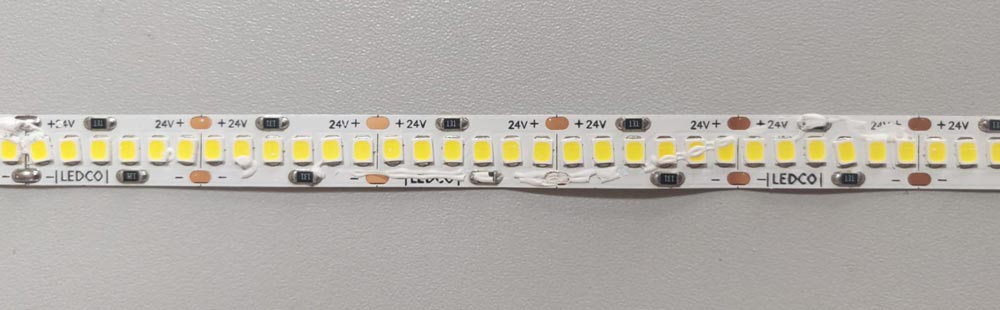

In the case of 24V strips, the maximum length per power point is 10 meters, while for 12V strips it is 5 meters, for lengths greater than those indicated we recommend powering the strip from both ends.

In the case of LED strips with a flexible track less than 10mm wide, we recommend re-feeding it every 5 meters.

5) Follow the cutting lines to make changes on the strip

All Ledco strips have cut indicators on the length of the flexible track, it is important to select the strip at the points indicated, otherwise a sector could be interrupted causing the last LEDs to go out.

You can find the information on the pre-set cutting distances for each LED strip in the instruction booklet, on the technical data sheets of our products or in the Ledco catalog.

6) Bend the strip in the correct direction

The LED strips can be curved but it is essential to follow the correct rays of curvatures and not to exceed the limit of them indicated in the instructions for use.

7) Pay attention to the voltage indicated on the strip for its use

It is important to respect the voltage indicated in the instructions of the led strip for its use.

Attaching a 24V led strip to a 220V system will cause permanent damage to the product.

For this it is important to use the transformers recommended by us with suitable voltage.

8) Use led strips with correct IP degree

Choosing a product with the right degree of protection is essential for the life of the LED strip.

If we need an outdoor strip, it will be important to choose a strip with IP65 or IP68, the degree of protection IP20 is only suitable for interiors where there is no contact of the strip with water or sources of high humidity.

In this article we have listed some important points to ensure the correct functioning of your LED strips and to never remain in the dark 😉

For other questions or concerns our technical department is always ready to support you regarding the correct use of the LED strips and will be able to indicate the most suitable product for your project.